MOISTURE BARRIER (also known as moister retarder): layer of plastic film or other material applied to the inner side of metal jacketing to inhibit jacket corrosion by interfering with the formation of a galvanic cell between the dissimilar metal of the pipe and jacket or by preventing crevice corrosion.

POLYKRAFT: multilayer composite film used as a moisture retarder on metal jacketing consisting of at least one layer of minimum 40 LB kraft paper and one or more layers of plastic film, usually polyethylene at a minimum thickness of 1.5 mils.

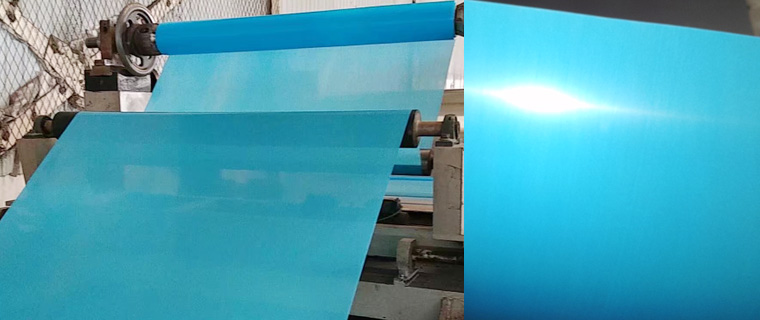

POLYSURLYN: a multilayer film used as a moisture retarder on metal jacketing

consisting of at least one layer of acid copolymer, surlyn and one or more layers of

other polymers, usually polyethylene.

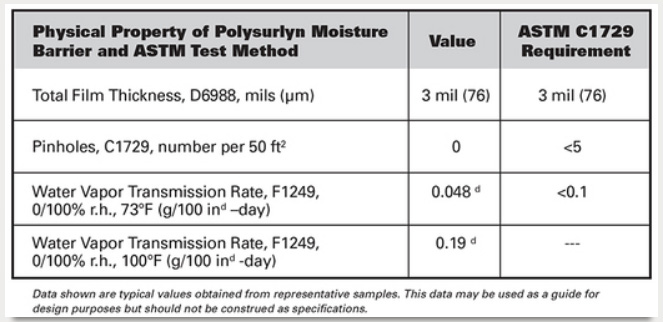

Aluminum Jacketing with a 3 mil polysurlyn moisture barrier has been tested for flammability using the industry standard ASTM E84 test method. The results were: ASTM E84 Flame Spread Index = 0 ASTM E84 Smoke Developed Index = 5 (Tested with exterior metal surface exposed to the flame)

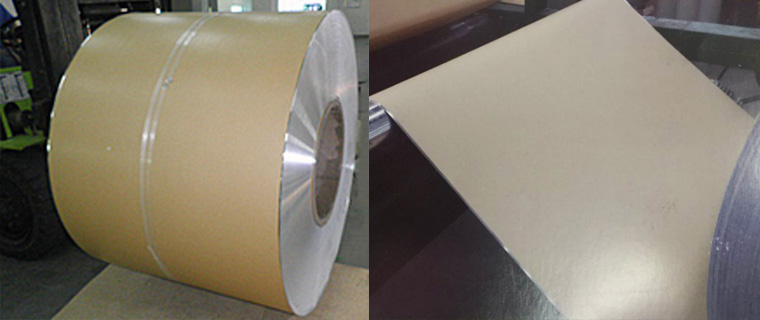

Stucco Embossed Finish is also can called stucco emobossed aluminum cladding .This is another popular finish used for aluminum jacketing. The stucco-like surface texture hides small imperfections and scratches caused by physical damage during or after installation. This finish also reduces reflectivity while still looking very professional. Lastly, the use of stucco embossed finish provides a small increase to the rigidity and strength of the aluminum jacketing.