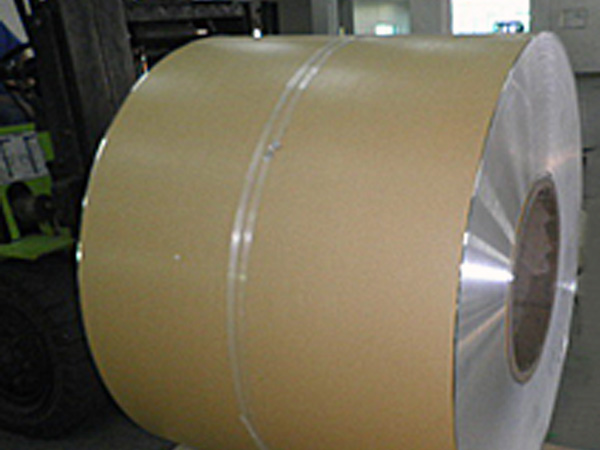

Aluminum Jacketing products can be supplied with a kraft (1 1/2 mil polyethylene) or a 3 mil polysurlyn moisture barrier which is heat and pressure bonded to the interior surface. A moisture barrier helps prevent galvanic corrosion caused by contact of dissimilar metals in the presence of moisture or chemical corrosion caused by installing sheets over damp insulation materials.

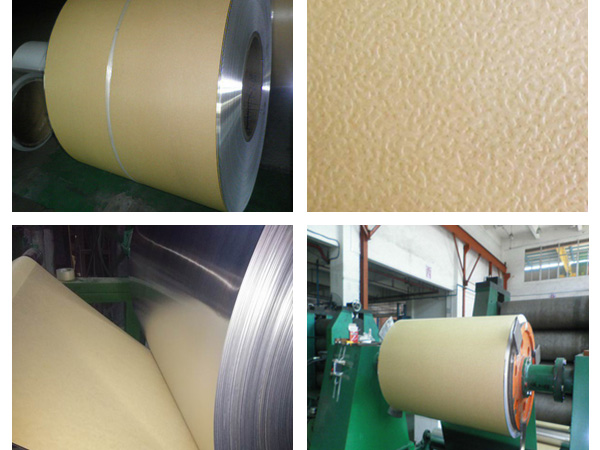

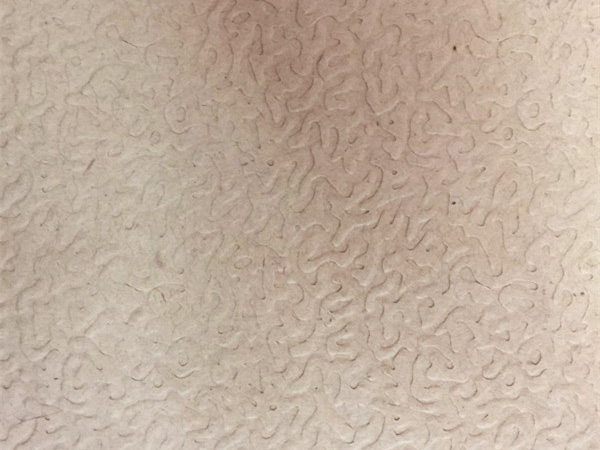

HAOMEI Aluminum jacketing (also called cladding) is available in mill finish, smooth, stucco embossed surface finishes with moisture barrier consisting of polykraft and Polysurlyn . At present, we can supply 1050/1060/1100 pure aluminium roll, 3003/3105/3004 anti-rust aluminium roll etc. With beautiful apperance, bright and clean. And good suitable for pipelines' insulation covered application. It also called thermal insulation aluminium roll, heat insulation aluminium roll.

The products are divided into two categories:1:Mill finish;2:aluminum jacketing

1.Aluminum Jacketing is recommended for HVAC, Insulated Piping, Tanks & vessels less than 8 feet in diameter.

2.Deep corrugated sheets are recommended for diameters greater than 8 feet.

3.Chemical Plants & Refineries: Distillation columns, tank farms, fractionation units, cokers and ethylene production units.

4.Paper Mills: Chemical storage tanks, breechings and ducts.

5.Steel Mills: Pickle acid tanks, oxygen production units, fuel oil and tar storage tanks.

6.Miscellaneous: Power station, Food processing plants, LPG storage units, LNG storage units, sewage and waste water treatment plants.